Metal Powders

Aluminum Powder | Purity: >99.7%

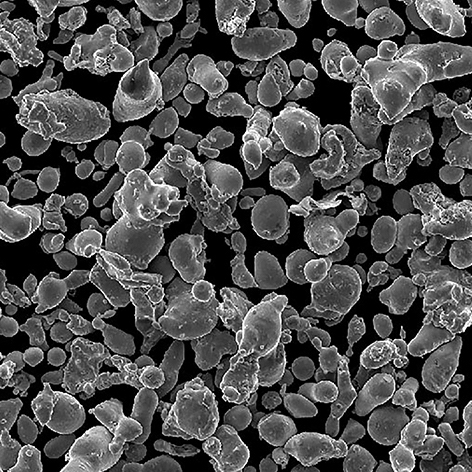

Atomized aluminum powder in irregular shapes

Atomised aluminum powder is used in the chemical industry as catalyst and in the refractory industry. It is used in the manufacturing processes of many products, including autoclave aerated concrete, cosmetic colorants, fingerprint powder, metallic paint, pyrotechnics, solid rocket and missile fuel, explosives and thermite.

Aluminum specification (Purity: 99.7%)

| Bi | 0.001 | V | 0.001 | Ni | 0.001 | K | 0.001 | Cd | 0.001 |

| Cr | 0.001 | Ag | 0.001 | Si | 0.09 | Mo | 0.001 | Fe | 0.12 |

| In | 0.001 | Ba | 0.001 | Tl | 0.001 | Pb | 0.001 | Li | 0.001 |

| Mn | 0.001 | Co | 0.001 | As | 0.001 | Sn | 0.02 | Na | 0.001 |

| P | 0.001 | Ga | 0.001 | Ca | 0.001 | Zn | 0.03 | Sb | 0.001 |

| Sr | 0.001 | Mg | 0.001 | Cu | 0.02 | B | 0.001 | Ti | 0.001 |

Size distribution analysis (µm)

| Product Code | Apparent density (g/cm3) | D3 | D6 | D10 | D16 | D25 | D50 | D75 | D84 | D90 | D97 | D99 |

| G-Al-20 | 1.14 | 1.77 | 2.58 | 3.36 | 4.31 | 5.58 | 9.34 | 15.06 | 18.4 | 21.73 | 29.15 | 30.2 |

| G-Al-45 | 1.04 | 3.584 | 4.622 | 5.683 | 7.038 | 8.957 | 14.68 | 22.07 | 25.82 | 29.22 | 36.20 | 45.1 |

| G-Al-63 | 1.06 | 7.80 | 9.68 | 11.67 | 14.17 | 17.47 | 26.2 | 37.21 | 43.01 | 48.64 | 61.05 | 63.2 |

| G-Al-100 | 1.06 | 10.98 | 14.41 | 18.08 | 22.91 | 29.66 | 48.91 | 74.92 | 89.28 | 103.7 | 136.8 | 139.4 |

| G-Al-63-250 | 1.01 | 38.49 | 47.89 | 56.55 | 66.79 | 79.92 | 114.7 | 161.2 | 188.6 | 215.1 | 275.3 | 300.5 |

| G-Al-420 | 0.997 | 31.86 | 44.86 | 56.91 | 70.7 | 87.87 | 133.8 | 197.8 | 235.1 | 173.6 | 366.2 | 400.3 |

Copper Powder

Technical data will follow shortly.

Copper powder is suitable for most powder metallurgy applications thanks to its high flow rate and good strength. When high purity copper powder is specifiedIt, it can be used in electronic and electrical applications requiring high conductivity. Hydrometallurgical processing generally yields a powder having fine particle sizes, low apparent density and high strength. With these properties, it is particularly suited for use in friction materials. Powders produced by solid-state reduction have characteristics similar to those of atomized powders and are suitable for the same applications.